There are many reasons to ensure your scaffolding is safe and secure, and one important part of this is to test the scaffold anchor ties.

The bones of scaffolding are made up of heavy metal tubes – each capable of inflicting heavy damage to people or property. Stack many of them up to the height of modern buildings in a populated high street, or a busy building site, and you have the potential for a disaster.

Even if damage or fatalities are avoided during a collapse – the scaffolder responsible could face a hefty fine and a custodial sentence. Also, the debris will have to be cleared and the scaffold rebuilt, causing a delay in completion and many wasted hours or days, resulting in further costs.

What are scaffold anchor ties and what do they do?

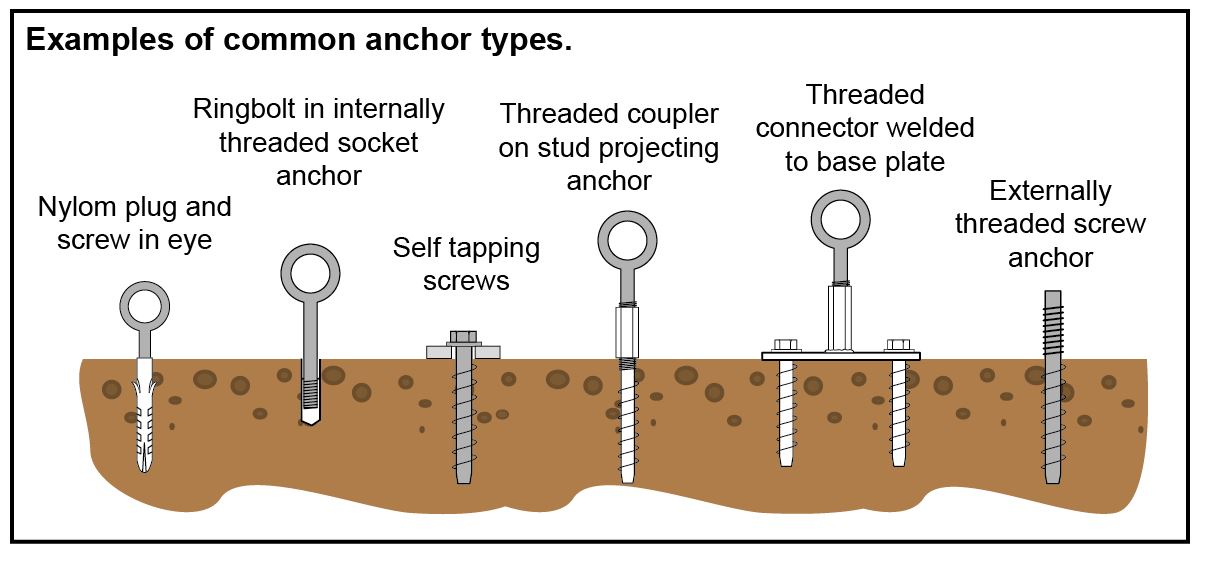

The National Access & Scaffolding Confederation (NASC) is the trade body for access and scaffolding in the UK. The NASC Guidance Note ‘TG4:19 – Anchorage Systems for Scaffolding’ describes several common anchor types, such as drop-in anchors, self-tapping screws, and ring bolts.

Pictured above: Some examples of common anchor types.

A scaffold tie is an important connection that fastens the scaffolding to a solid building or body to prevent it from collapsing. When installed properly in a system they create resistance to opposing forces such as high winds and vehicle collisions.

How should you test them?

An anchor may be strong enough and specifically approved for the job but if installed incorrectly or into a weak material it will be compromised and potentially fail. That’s why testing on-site in actual working conditions is so important.

The NASC Guidance Note ‘TG4:19 – Anchorage Systems for Scaffolding’ sets out requirements for two types of tests:

– PRELIMINARY TESTS of scaffold anchors – to check the suitability and allowable loads of an anchor type in a particular base material

– PROOF TESTS – sample tests to check that anchors have been installed correctly – to be carried out on all jobs.

The TG4:19 describes a proof Load testing requirement for a tensile test of 1.5 x the design load. For heavy-duty ties with a capacity of 12.2kN, this means a test load of 18.3kN.

The TG4:19 also describes the frequency of tests and appropriate quantities.

Download a copy from the NASC website for more information.

What can you use to test them?

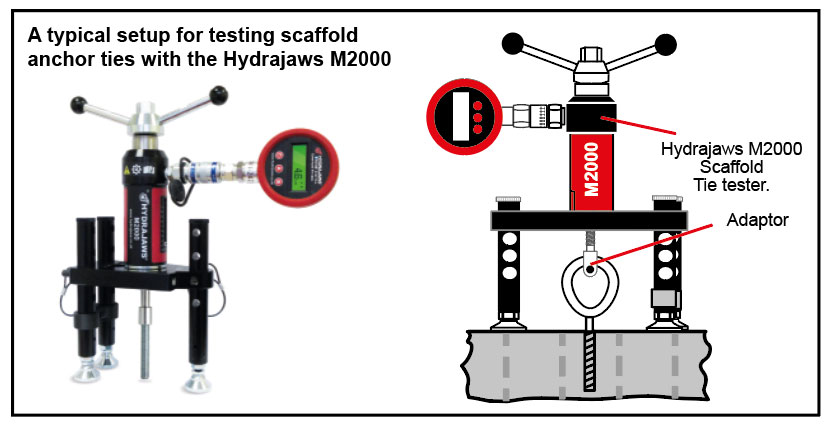

The Hydrajaws M2000 Scaffold Tie Tester Kit is specifically designed for this job. It is easy to use and light to transport. It comes complete with a comprehensive full-colour user manual and the backing and support of our technical team at Hydrajaws.

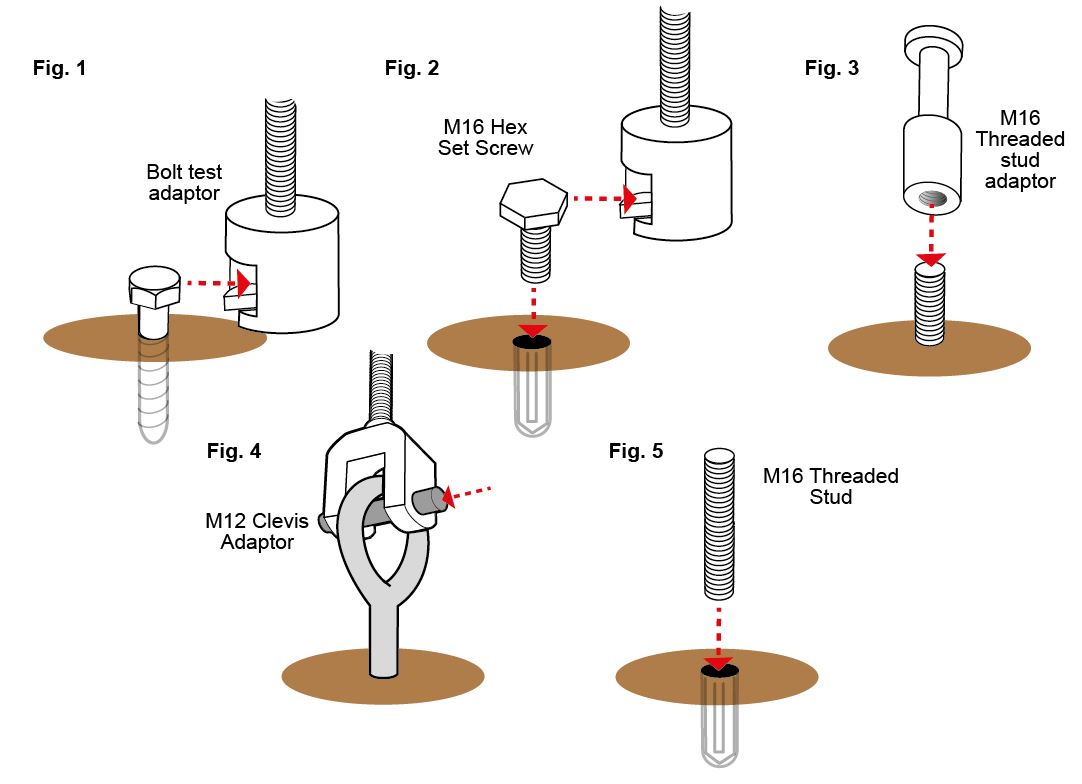

The Hydrajaws kit comes with several adaptors, to fit many common anchor tie fixings, including:

1. Bolt test adaptor. This will test a typical hex bolt screw. This may have to be loosened off slightly to get underneath (fig 1).

2. M16 Hex set. This can be placed in anchor holes and used with the ring bolt adaptor (fig 2).

3. M16 Threaded stud adaptor. This can test anchors with exposed thread (fig 3).

4. M12 Ring bolt Clevis adaptor. It is used to test a typical eye bolt or anchors with screw-in eyes (fig 4).

5. M16 Thread. Used with the threaded stud adaptor, this can test anchor points where no thread is exposed (fig 5).

And the height-adjustable legs give the unit extra reach and the strength required for Scaffold Tie Tests.

Who can you trust to provide equipment?

You want your scaffold to be safe, compliant, professional, and stable. At Hydrajaws we have been making portable tension testers for over 30 years and have the experience and knowledge to provide support and advice to help you avoid any problems testing the ties. All kits come with a full colour manual and several helpful videos are available online.

Scaffold safety can never be underestimated so only trust reliable and established suppliers – especially for your test equipment.

Call Hydrajaws at 01675 430 370 or email [email protected] for our latest deals.